Boost Manufacturing Performance with Industrial Gas Grills

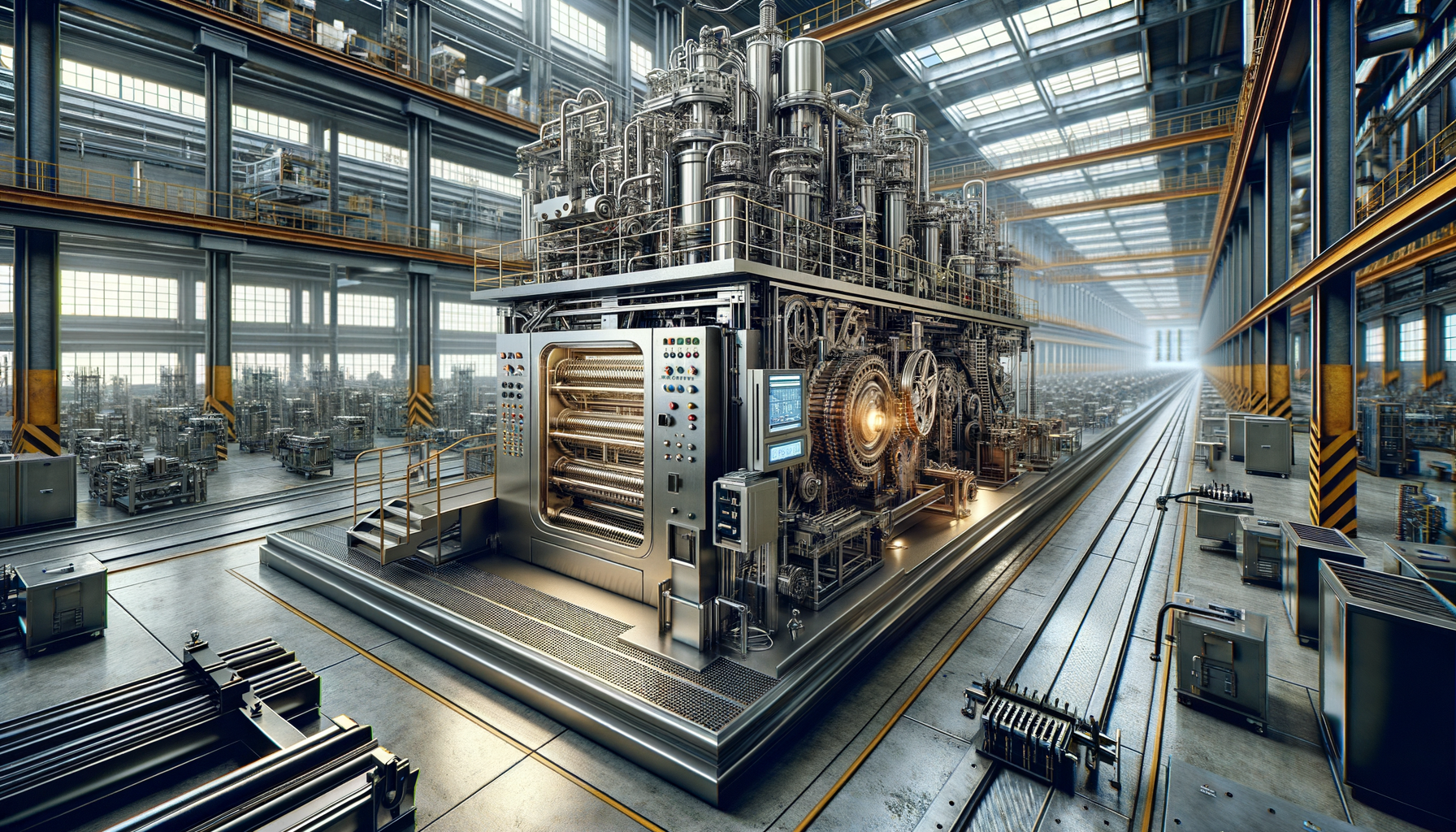

The Role of Industrial Gas Grills in Manufacturing

Industrial gas grills have become a cornerstone in modern manufacturing due to their efficiency and versatility. These machines are designed to handle large-scale production tasks, providing a consistent and reliable heat source. Their ability to maintain precise temperature control is essential for processes that require uniform heating, such as in the food and beverage industry or metal fabrication. The grills are equipped with advanced technology that allows for automation, reducing the need for manual oversight and increasing production rates.

One of the primary benefits of using industrial gas grills is their energy efficiency. They utilize natural gas or propane, which are more cost-effective compared to electric alternatives. This not only reduces operational costs but also minimizes the environmental impact, aligning with the growing demand for sustainable manufacturing practices. Additionally, these grills are designed to be robust and durable, capable of withstanding the rigors of continuous operation.

In summary, industrial gas grills are indispensable in manufacturing due to their ability to enhance productivity, reduce costs, and support sustainable practices. Their role is crucial in ensuring that manufacturing processes are not only efficient but also environmentally responsible.

Technological Advancements in Industrial Gas Grills

The evolution of industrial gas grills has been marked by significant technological advancements that have transformed their functionality and efficiency. Modern grills are equipped with digital controls and sensors that allow for precise temperature regulation. This level of control is vital in industries where specific temperature settings are crucial for product quality, such as in the chemical and food processing sectors.

Moreover, the integration of IoT (Internet of Things) technology has revolutionized how these machines are monitored and maintained. Operators can now receive real-time data on grill performance, enabling predictive maintenance and reducing downtime. This proactive approach to maintenance ensures that the grills operate at optimal efficiency, extending their lifespan and reducing repair costs.

Another notable advancement is the development of modular designs. These designs allow for easy upgrades and customization, enabling manufacturers to adapt their equipment to changing production needs without significant investment. This flexibility is particularly beneficial in industries that experience frequent shifts in consumer demand.

Overall, technological advancements have significantly enhanced the capabilities of industrial gas grills, making them more efficient, reliable, and adaptable to the dynamic needs of modern manufacturing.

Comparing Industrial Gas Grills to Electric Alternatives

When it comes to choosing between industrial gas grills and electric alternatives, several factors need to be considered. Each type of grill offers distinct advantages and potential drawbacks, depending on the specific requirements of the manufacturing process.

Gas grills are renowned for their rapid heating capabilities and consistent temperature maintenance. This makes them ideal for processes that require quick temperature adjustments and high heat intensity. Additionally, gas grills tend to have lower operational costs due to the lower price of natural gas compared to electricity.

On the other hand, electric grills offer precise temperature control and are often easier to install, as they do not require gas lines. They are also considered safer in environments where gas leaks could pose a risk. However, electric grills may have higher energy costs and are generally slower to reach desired temperatures compared to their gas counterparts.

In conclusion, the choice between gas and electric industrial grills depends largely on the specific needs of the manufacturing process, including factors such as cost, safety, and heating requirements.

Applications of Industrial Gas Grills Across Industries

Industrial gas grills are utilized across a wide range of industries, each benefiting from their unique features and capabilities. In the food industry, these grills are essential for large-scale cooking and baking operations, where consistent heat is crucial for product quality. The ability to maintain precise temperatures ensures that food products are cooked evenly, enhancing both taste and safety.

In the metal fabrication industry, gas grills are used for processes such as annealing and tempering. The high heat output and uniform distribution provided by these grills are vital for altering the physical properties of metals, making them more durable and suitable for various applications.

The chemical industry also relies heavily on industrial gas grills for processes that require controlled heating, such as distillation and chemical synthesis. The ability to maintain stable temperatures is crucial for ensuring reaction efficiency and product consistency.

Overall, the versatility of industrial gas grills makes them an invaluable asset across multiple industries, providing the necessary heat control and efficiency required for diverse manufacturing applications.

Future Trends in Industrial Gas Grill Technology

As industries continue to evolve, so too does the technology behind industrial gas grills. One of the emerging trends is the integration of artificial intelligence (AI) to further enhance automation and efficiency. AI can analyze data from grill sensors to optimize heating processes and predict maintenance needs, reducing downtime and improving productivity.

Another trend is the development of eco-friendly models that aim to reduce carbon emissions. These grills are designed to operate with renewable energy sources, such as biogas, or incorporate energy recovery systems to minimize waste. This aligns with the global push towards sustainable manufacturing practices and regulatory requirements for reducing environmental impact.

Additionally, there is a growing focus on enhancing user interfaces to make these machines more intuitive and accessible. Touchscreen controls and remote monitoring capabilities are becoming standard features, allowing operators to manage grill operations with ease and precision.

In conclusion, the future of industrial gas grills looks promising, with advancements focused on improving efficiency, sustainability, and user experience. These developments are set to further solidify the role of gas grills in modern manufacturing.