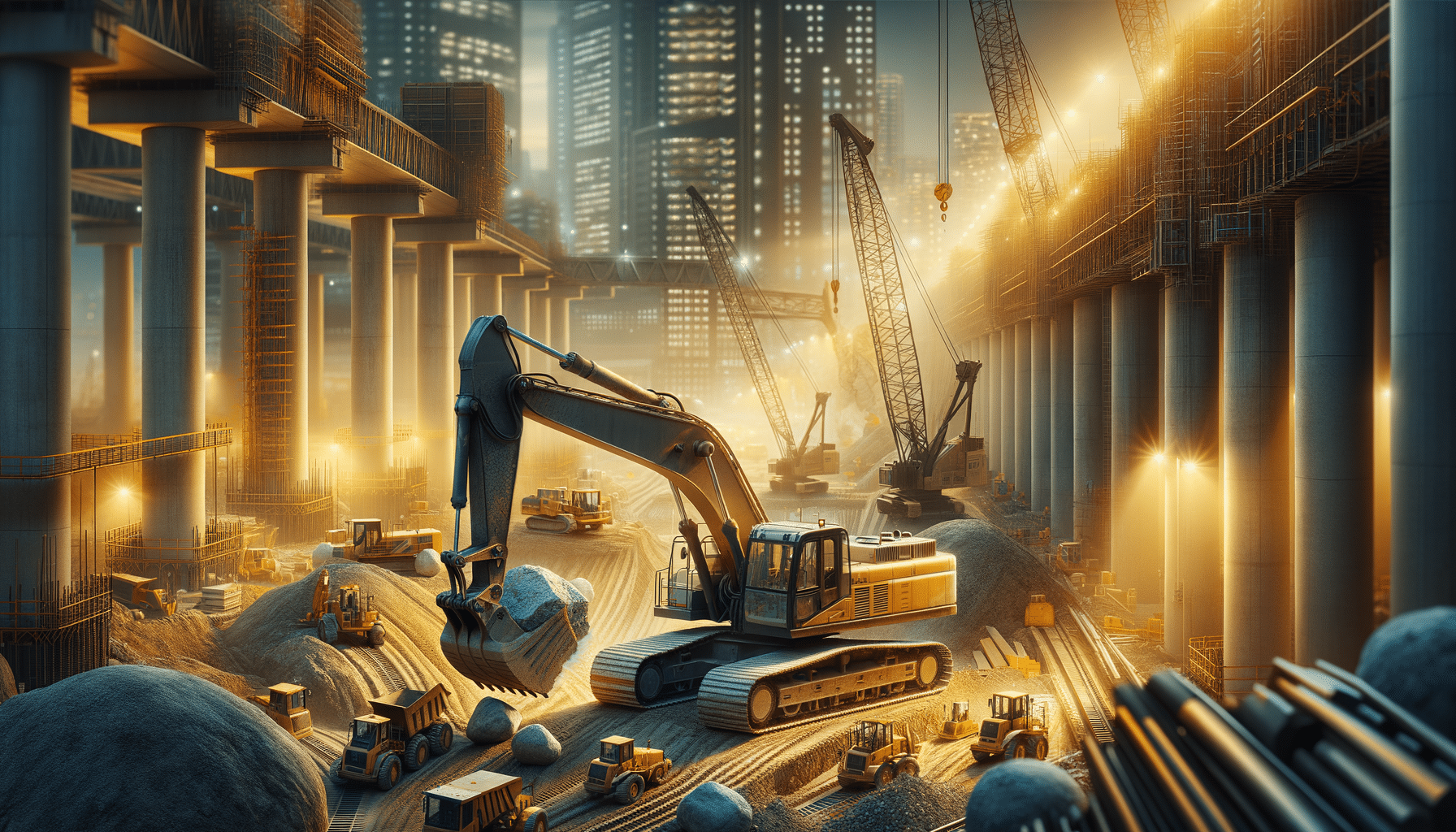

Excavators: The Heavy-Duty Machines Driving Construction Forward.

Introduction to Excavators

Excavators are a cornerstone in the construction industry, offering unparalleled versatility and power. These heavy-duty machines are designed to handle a wide range of tasks, from digging trenches and demolishing structures to lifting heavy materials. Their robust hydraulic systems enable them to dig deep, move large amounts of earth, and reach areas that other equipment cannot. As construction projects become more complex and demanding, the role of excavators becomes increasingly critical, ensuring projects are completed faster, safer, and more cost-effectively.

Types of Excavators

Excavators come in various types, each tailored to specific tasks and environments. The most common types include:

- Crawler Excavators: Known for their stability and ability to operate on uneven terrain, these excavators are equipped with tracks instead of wheels.

- Wheeled Excavators: These are faster and more maneuverable on paved surfaces, making them ideal for urban construction projects.

- Mini Excavators: Compact and versatile, mini excavators are perfect for small-scale projects and confined spaces.

- Long Reach Excavators: With extended arms, these machines can reach further distances, making them suitable for dredging and demolition tasks.

Each type of excavator is designed to optimize efficiency and performance in its intended environment, ensuring that construction tasks are completed with precision and speed.

Key Features and Innovations

Modern excavators are equipped with a range of features and innovations that enhance their functionality and efficiency. Some of these include:

- Advanced Hydraulic Systems: These systems provide the power and precision needed for complex digging and lifting tasks.

- GPS and Telematics: These technologies offer real-time data on equipment location, performance, and maintenance needs, improving operational efficiency.

- Eco-Friendly Engines: Many excavators now feature engines that reduce emissions and fuel consumption, aligning with environmental sustainability goals.

- Attachment Versatility: A wide range of attachments, such as buckets, hammers, and grapples, allow excavators to perform diverse tasks beyond standard digging.

These innovations not only enhance the capabilities of excavators but also contribute to safer and more efficient construction practices.

Applications Across Industries

While primarily associated with construction, excavators are utilized across various industries due to their versatility. Some key applications include:

- Landscaping: Excavators are used for tasks such as grading, trenching, and planting, making them invaluable in creating and maintaining landscapes.

- Mining: In mining operations, excavators are essential for removing overburden and extracting minerals.

- Agriculture: These machines assist in tasks like digging irrigation channels and clearing land for farming.

- Forestry: Excavators equipped with specialized attachments are used for tree felling, log handling, and land clearing.

The adaptability of excavators makes them a vital tool across these industries, contributing to increased productivity and efficiency.

Future Trends and Developments

The future of excavators is shaped by technological advancements and evolving industry demands. Some anticipated trends include:

- Automation and Robotics: The integration of autonomous systems and robotics is expected to enhance precision and reduce the need for manual operation.

- Electric and Hybrid Models: As the push for sustainability grows, electric and hybrid excavators are becoming more prevalent, offering reduced emissions and operational costs.

- Smart Technology: The incorporation of smart technology will enable excavators to communicate with other machines and systems, optimizing workflow and resource management.

These trends indicate a shift towards more efficient, environmentally friendly, and technologically advanced excavators, poised to meet the challenges of future construction and industrial projects.