Industrial Machines: Powering Production

Introduction to Industrial Machines

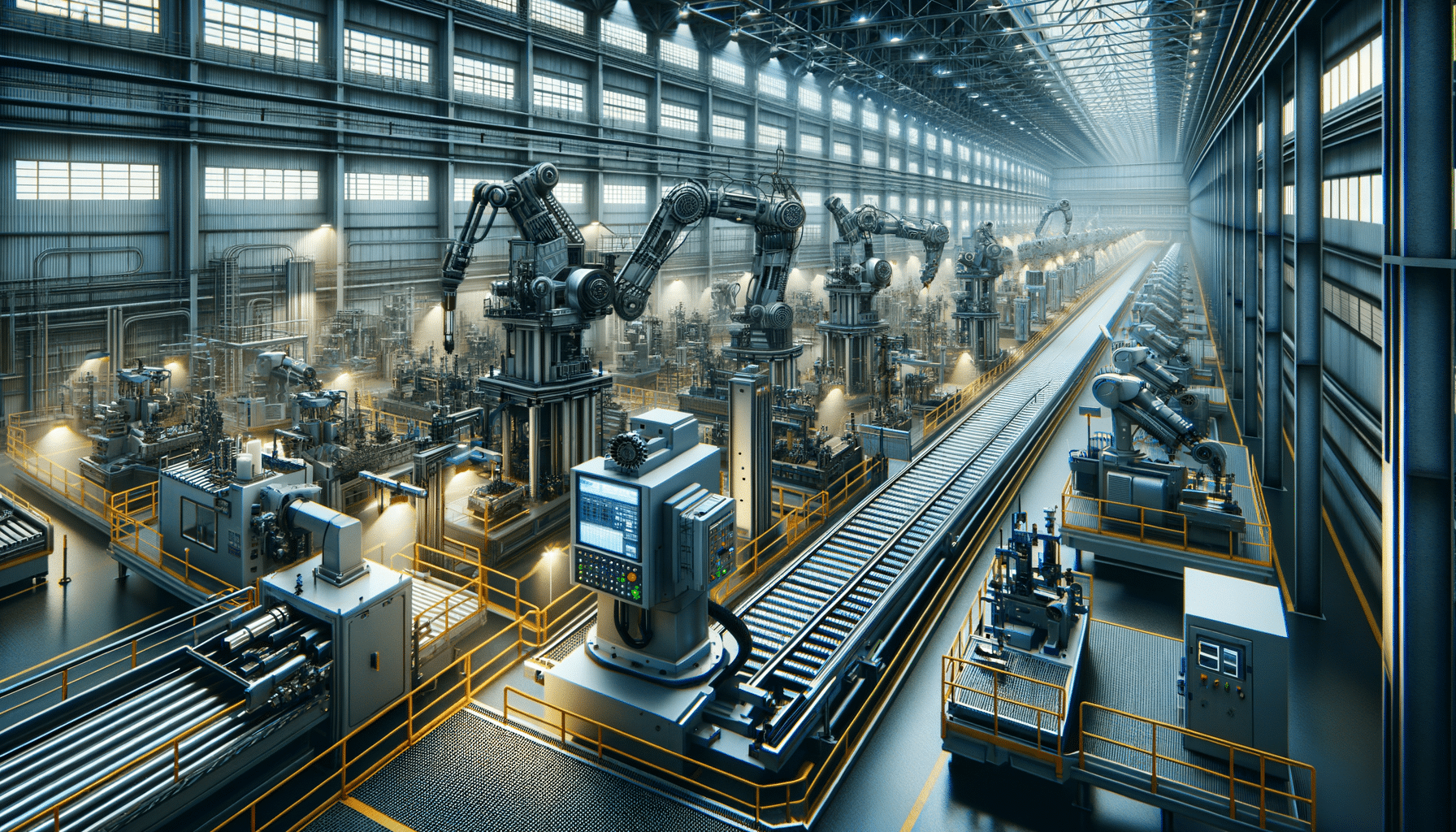

In the modern industrial landscape, machines play a pivotal role in driving efficiency and productivity. Industrial machines are the backbone of various sectors, enabling companies to perform complex tasks with precision and speed. These machines are crucial for mass production, reducing human error, and improving overall output quality. As industries continue to evolve, the demand for advanced machinery that can handle more sophisticated tasks is on the rise.

Industrial machines are not just about automation; they are about enhancing the capabilities of human labor. By taking over repetitive and physically demanding tasks, these machines allow human workers to focus on more strategic and creative aspects of production. This synergy between man and machine is what powers the industrial sector today, making it more competitive and innovative.

The significance of industrial machines cannot be overstated. They are essential for meeting the high demands of global markets, ensuring that products are manufactured quickly and efficiently. From automotive to food processing, industrial machines are integral to the operations of countless industries.

Types of Industrial Machines

Industrial machines come in various forms, each designed to serve specific functions within a production line. Understanding the different types of machines is crucial for businesses aiming to optimize their manufacturing processes.

Some of the most common types of industrial machines include:

- Conveyor Systems: These machines are used to transport materials from one point to another within a facility. They are essential for streamlining the movement of goods, reducing manual handling, and increasing speed.

- CNC Machines: Computer Numerical Control (CNC) machines are used for precision cutting, drilling, and milling. They are highly accurate and can produce complex parts with minimal waste.

- Robotic Arms: These machines are used for tasks such as welding, painting, and assembly. They are highly flexible and can be programmed to perform a variety of tasks, making them invaluable in manufacturing environments.

- 3D Printers: Although relatively new in the industrial sector, 3D printers are revolutionizing production by allowing for rapid prototyping and on-demand manufacturing.

Each type of machine has its own set of advantages and is suited to different applications. By selecting the right machines, businesses can enhance their production capabilities and remain competitive in their respective industries.

The Impact of Industrial Machines on Productivity

Industrial machines have a profound impact on productivity, transforming how goods are manufactured and delivered. By automating repetitive tasks, these machines significantly reduce the time and effort required to produce goods, leading to higher output levels.

One of the key benefits of industrial machines is their ability to operate continuously without fatigue. Unlike human workers, machines can work around the clock, ensuring that production lines remain operational and efficient. This continuous operation is crucial for meeting tight deadlines and fulfilling large orders.

Moreover, industrial machines enhance consistency and quality in production. With precise control over manufacturing processes, these machines ensure that each product meets the required specifications, reducing the likelihood of defects and waste.

Additionally, the integration of advanced technologies such as artificial intelligence and machine learning is further boosting the capabilities of industrial machines. These technologies enable machines to learn from data, optimize their operations, and even predict maintenance needs, thereby minimizing downtime and maximizing productivity.

Challenges and Future Trends in Industrial Machinery

Despite their numerous advantages, industrial machines also present certain challenges. One of the primary concerns is the high initial investment required to acquire and set up these machines. For small and medium-sized enterprises, this can be a significant barrier to entry.

Another challenge is the need for skilled operators and technicians who can manage and maintain these machines. As machines become more advanced, the demand for workers with specialized knowledge and expertise increases, highlighting the importance of ongoing training and education.

Looking to the future, the industrial machinery sector is poised for significant advancements. Emerging technologies such as the Internet of Things (IoT), augmented reality, and blockchain are expected to revolutionize how machines are used and managed. These innovations will enable smarter and more connected production environments, where machines can communicate with each other and with human operators in real-time.

As industries continue to embrace digital transformation, the role of industrial machines will only grow in importance, paving the way for more efficient and sustainable manufacturing practices.

Conclusion: The Essential Role of Industrial Machines

Industrial machines are indispensable in today’s fast-paced manufacturing landscape. They are the driving force behind efficient production, enabling businesses to meet the demands of a competitive market. By automating tasks, enhancing precision, and boosting productivity, these machines help companies achieve their operational goals while maintaining high standards of quality.

As technology continues to evolve, the capabilities of industrial machines will expand, offering even greater opportunities for innovation and growth. It is crucial for businesses to stay informed about these developments and adapt their strategies accordingly to remain at the forefront of their industries.

In conclusion, industrial machines are more than just tools; they are key enablers of progress and success in the industrial sector. By harnessing their potential, businesses can unlock new levels of efficiency and competitiveness, ensuring their long-term sustainability and prosperity.