Industrial Machines: Supporting Heavy Work with Precision

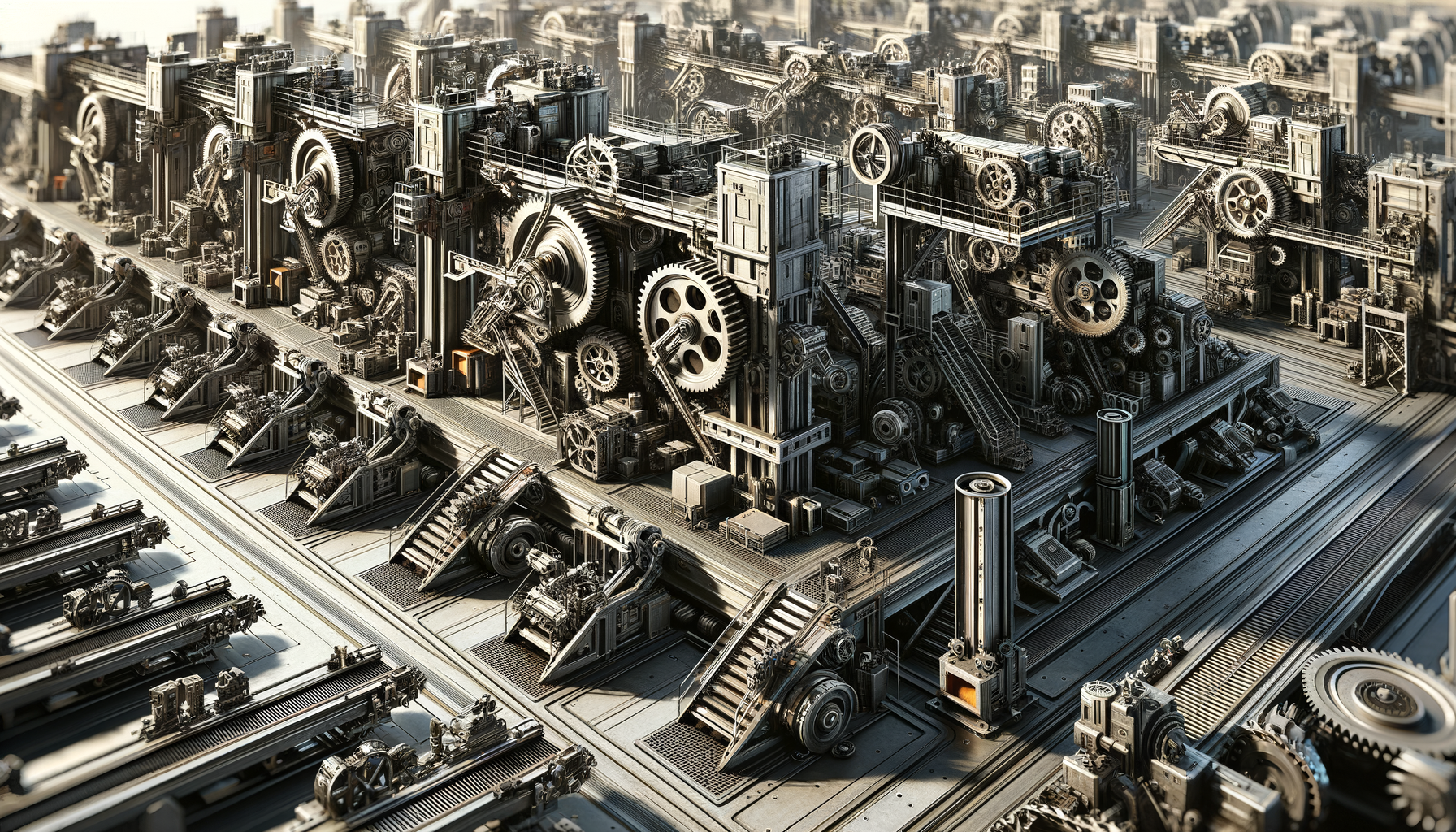

Introduction to Industrial Machines

Industrial machines are the backbone of modern manufacturing and production. In factories, workshops, and large-scale operations, they are essential for performing tasks that require precision and efficiency. These machines are designed to handle complex operations such as cutting, shaping, assembling, and packaging with consistent accuracy. Their role in improving workflow, reducing manual labor, and maintaining product quality cannot be overstated. By automating repetitive tasks, industrial machines allow human workers to focus on more strategic and creative aspects of production, thereby enhancing overall productivity.

The Evolution of Industrial Machines

The journey of industrial machines from rudimentary tools to sophisticated systems is a testament to human ingenuity. The Industrial Revolution marked a significant turning point, with steam engines and mechanized looms leading the charge in transforming production processes. Over time, the introduction of electricity and digital technology further revolutionized industrial machinery. Today, machines are equipped with advanced sensors and computer systems, enabling them to perform tasks with remarkable precision and speed. This evolution has not only increased the efficiency of production lines but also paved the way for the development of smart factories that leverage the Internet of Things (IoT) and artificial intelligence to optimize operations.

Types of Industrial Machines

The diversity of industrial machines reflects the varied needs of different sectors. Some common types include:

- CNC Machines: Computer Numerical Control (CNC) machines are used for cutting and shaping materials with high precision. They are widely used in metalworking and woodworking industries.

- Robotic Arms: These machines are essential in assembly lines, where they perform repetitive tasks such as welding, painting, and packaging.

- 3D Printers: Revolutionizing prototyping and manufacturing, 3D printers create objects by layering materials based on digital designs.

- Conveyor Systems: Used for transporting materials within a facility, conveyor systems streamline the movement of goods, enhancing efficiency.

Each type of machine is tailored to meet specific production requirements, ensuring that industries can achieve their operational goals effectively.

Benefits of Using Industrial Machines

The integration of industrial machines into production processes offers numerous advantages:

- Increased Efficiency: Machines can operate continuously without fatigue, significantly boosting production rates and reducing downtime.

- Consistency and Quality: Machines perform tasks with uniform precision, ensuring consistent product quality and reducing the likelihood of defects.

- Cost Reduction: By automating tasks, companies can reduce labor costs and minimize waste, leading to substantial savings.

- Safety Improvements: Machines can handle dangerous tasks, reducing the risk of workplace injuries and creating a safer environment for workers.

These benefits highlight the pivotal role of industrial machines in enhancing the competitiveness and sustainability of modern industries.

Future Trends in Industrial Machinery

The future of industrial machinery is poised for exciting advancements. The integration of artificial intelligence and machine learning is expected to enhance the capabilities of machines, allowing them to adapt to changing production needs autonomously. Additionally, the rise of Industry 4.0 is driving the development of interconnected systems that can communicate and collaborate in real-time. This connectivity will enable predictive maintenance, reducing downtime and extending the lifespan of machines. Furthermore, the focus on sustainability is leading to the creation of energy-efficient machines that minimize environmental impact. As these trends continue to unfold, industrial machines will play an increasingly vital role in shaping the future of manufacturing and production.