The Role of Industrial Machines in Modern Life

Introduction to Industrial Machines

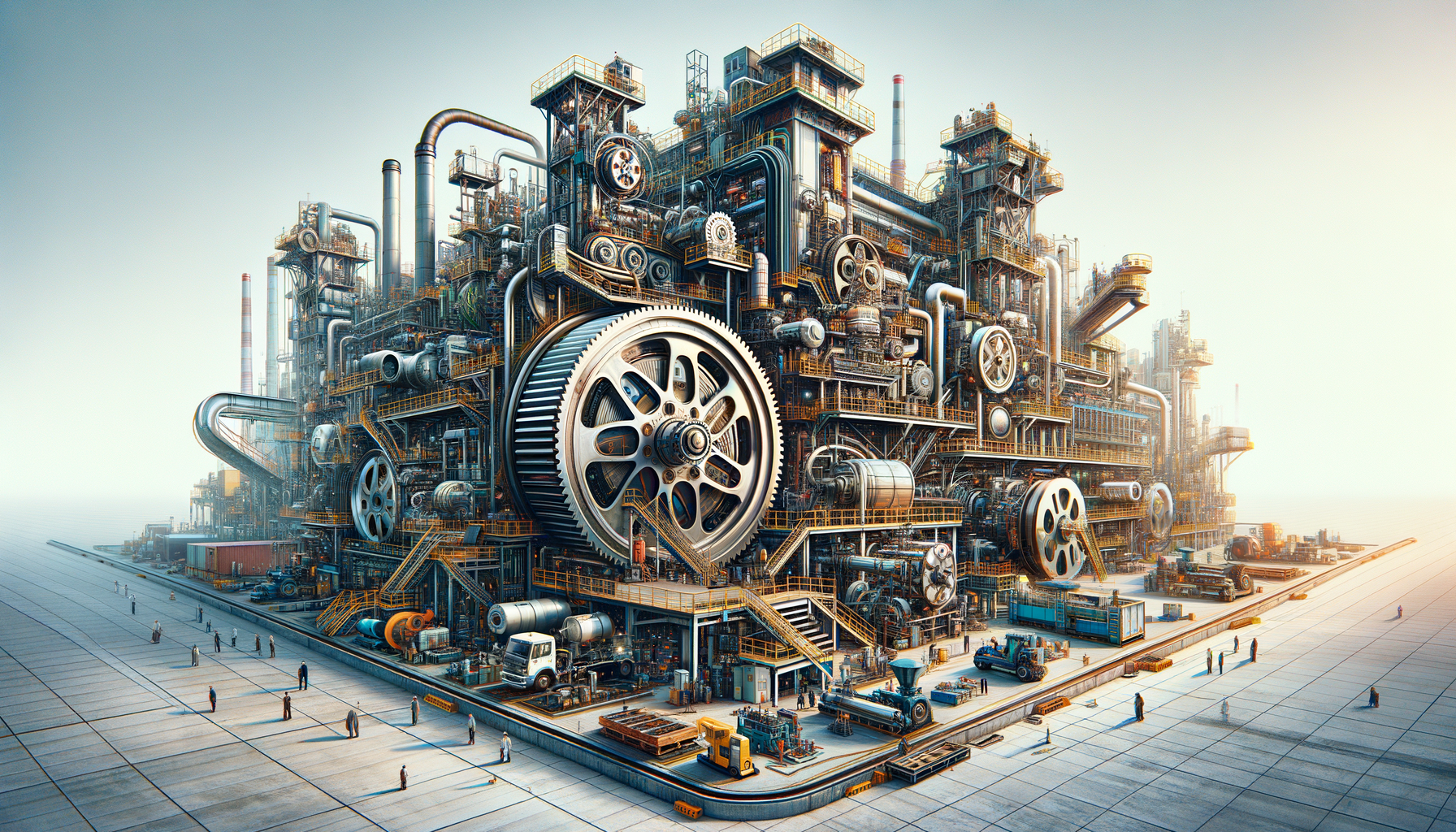

Industrial machines have become the backbone of modern manufacturing, revolutionizing the way goods are produced and services are delivered. From the assembly lines of automotive plants to the intricate processes in electronics fabrication, industrial machines play a crucial role in enhancing efficiency, precision, and productivity. These machines range from simple mechanical devices to complex automated systems that integrate robotics and artificial intelligence. Understanding their functions and capabilities is essential for businesses aiming to optimize their operations and remain competitive in a rapidly evolving market.

The Evolution of Industrial Machines

The evolution of industrial machines is a testament to human ingenuity and technological advancement. The Industrial Revolution marked the beginning of this transformation, introducing steam-powered machines that significantly increased production capacity. Over the years, technological advancements have led to the development of machines that are not only faster but also more precise and versatile. Today, we see the integration of digital technologies, such as the Internet of Things (IoT) and artificial intelligence, which have paved the way for smart factories and Industry 4.0. These advancements have enabled manufacturers to achieve unprecedented levels of efficiency and customization.

Types of Industrial Machines

Industrial machines can be categorized into several types based on their functions and applications. Some of the most common types include:

- CNC Machines: Computer Numerical Control machines are used for precision cutting and shaping of materials. They are widely used in metalworking, woodworking, and plastic manufacturing.

- Robots: These machines are used for tasks that require high precision and repeatability, such as welding, painting, and assembly.

- Conveyor Systems: Essential for material handling, these systems transport products and materials within a facility.

- Pumps and Compressors: Used in various industries for moving fluids and gases.

Each type of machine has its unique advantages and is chosen based on the specific needs of the production process.

Benefits of Industrial Machines

The integration of industrial machines into manufacturing processes offers numerous benefits, including:

- Increased Productivity: Machines can operate continuously without fatigue, significantly increasing output.

- Enhanced Precision: Advanced machines offer high precision and accuracy, reducing errors and waste.

- Cost Efficiency: While the initial investment may be high, the long-term savings in labor and material costs can be substantial.

- Safety Improvements: Machines can perform dangerous tasks, reducing the risk of injury to human workers.

These benefits make industrial machines an indispensable part of modern manufacturing operations.

The Future of Industrial Machines

The future of industrial machines is set to be even more transformative as technology continues to advance. Emerging trends include the use of additive manufacturing, or 3D printing, which allows for rapid prototyping and customization. Additionally, the integration of artificial intelligence and machine learning is enabling machines to perform complex tasks with minimal human intervention. The development of collaborative robots, or cobots, is also gaining traction, as they can work alongside humans to enhance productivity and safety. As these technologies evolve, industrial machines will continue to play a vital role in shaping the future of manufacturing and industry.