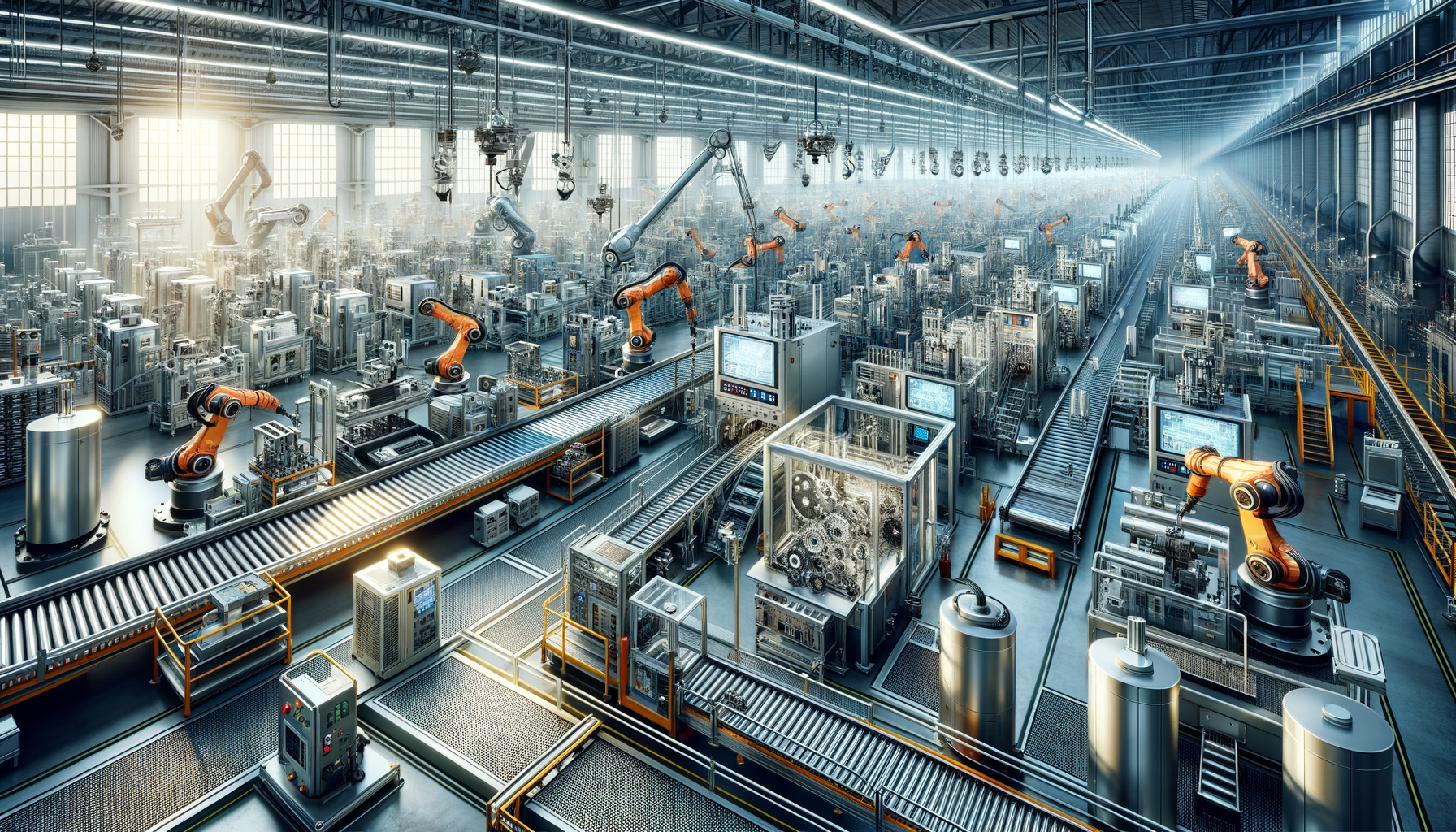

The Role of Industrial Machines in Modern Production

Industrial machines have become an integral part of modern production processes. They are designed to perform tasks that are repetitive, labor-intensive, or require high precision, which are often beyond human capability. By automating these tasks, industrial machines significantly enhance productivity and efficiency. These machines range from simple tools like conveyor belts to complex systems such as CNC machines and robotics that handle intricate manufacturing processes.

The importance of industrial machines is underscored by their ability to reduce production time and labor costs. For instance, in the automotive industry, assembly lines equipped with robotic arms can produce vehicles at a much faster rate than manual assembly. Additionally, industrial machines ensure consistency and quality in production, as they are programmed to perform tasks with precision and repeatability.

Furthermore, industrial machines contribute to workplace safety by taking over hazardous tasks. Machines can operate in environments that may be unsafe for humans, such as those involving extreme temperatures or exposure to toxic materials. By doing so, they help in minimizing the risk of workplace injuries and accidents.

Types of Industrial Machines and Their Applications

Industrial machines come in various forms, each tailored for specific applications. Some of the most common types include:

- Conveyor Systems: Used for transporting materials across different stages of production. They are widely used in industries like food processing, automotive, and packaging.

- CNC Machines: Computer Numerical Control machines are used for precise cutting, drilling, and milling. They are essential in metalworking, woodworking, and plastic manufacturing.

- Robotics: These machines are used for tasks that require high precision and speed, such as assembly, welding, and painting. Robotics are prevalent in the automotive and electronics industries.

- 3D Printers: Used for creating prototypes and complex parts. They are increasingly being adopted in aerospace, healthcare, and consumer goods manufacturing.

Each type of machine is designed to optimize specific processes, ensuring that production is not only efficient but also adaptable to changing demands and innovations.

Benefits of Integrating Industrial Machines in Production

The integration of industrial machines into production processes offers numerous benefits that extend beyond mere efficiency. One of the primary advantages is the improvement in product quality. Machines can perform tasks with a level of precision that is difficult to achieve manually, ensuring that each product meets the required standards.

Another significant benefit is the reduction of operational costs. Although the initial investment in industrial machines can be substantial, the long-term savings from reduced labor costs and increased production speed often justify the expense. Additionally, machines can operate continuously without fatigue, leading to higher output levels.

Moreover, industrial machines enable companies to respond swiftly to market demands. With the ability to quickly adjust production lines and scale operations, businesses can better meet customer needs and capitalize on new opportunities. This flexibility is particularly valuable in industries where market trends and consumer preferences change rapidly.

Challenges and Considerations in Utilizing Industrial Machines

While industrial machines offer numerous advantages, their integration into production processes is not without challenges. One of the primary considerations is the cost of acquisition and maintenance. High initial investments and ongoing maintenance expenses can be a barrier for small to medium-sized enterprises.

Another challenge is the need for skilled personnel to operate and maintain these machines. As technology advances, the complexity of industrial machines increases, requiring workers to have specialized skills and training. This can result in additional costs for employee training and development.

Furthermore, there is the challenge of ensuring compatibility and integration with existing systems. Companies must carefully evaluate their current infrastructure and processes to ensure that new machines can be seamlessly integrated without disrupting production.

The Future of Industrial Machines in Production

The future of industrial machines is shaped by technological advancements and the growing demand for automation. Emerging technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT) are set to revolutionize industrial machines, making them smarter and more efficient.

AI and machine learning enable machines to learn from data and improve their performance over time. This can lead to more efficient production processes and the ability to predict and prevent machine failures, reducing downtime and maintenance costs.

IoT connectivity allows machines to communicate with each other and with centralized systems, facilitating real-time monitoring and control. This connectivity can enhance decision-making processes by providing valuable insights into production efficiency and equipment performance.

As these technologies continue to evolve, industrial machines will play an even more critical role in driving innovation and competitiveness in various industries.

Leave a Reply