The Evolution of Ice Cream Makers

Ice cream has been a beloved treat for centuries, but the technology behind its production has evolved significantly. From hand-cranked machines to modern industrial ice cream makers, the journey reflects a blend of tradition and innovation. The early ice cream makers required manual effort and were limited in capacity, catering primarily to small-scale needs. However, as demand grew, so did the need for more efficient production methods.

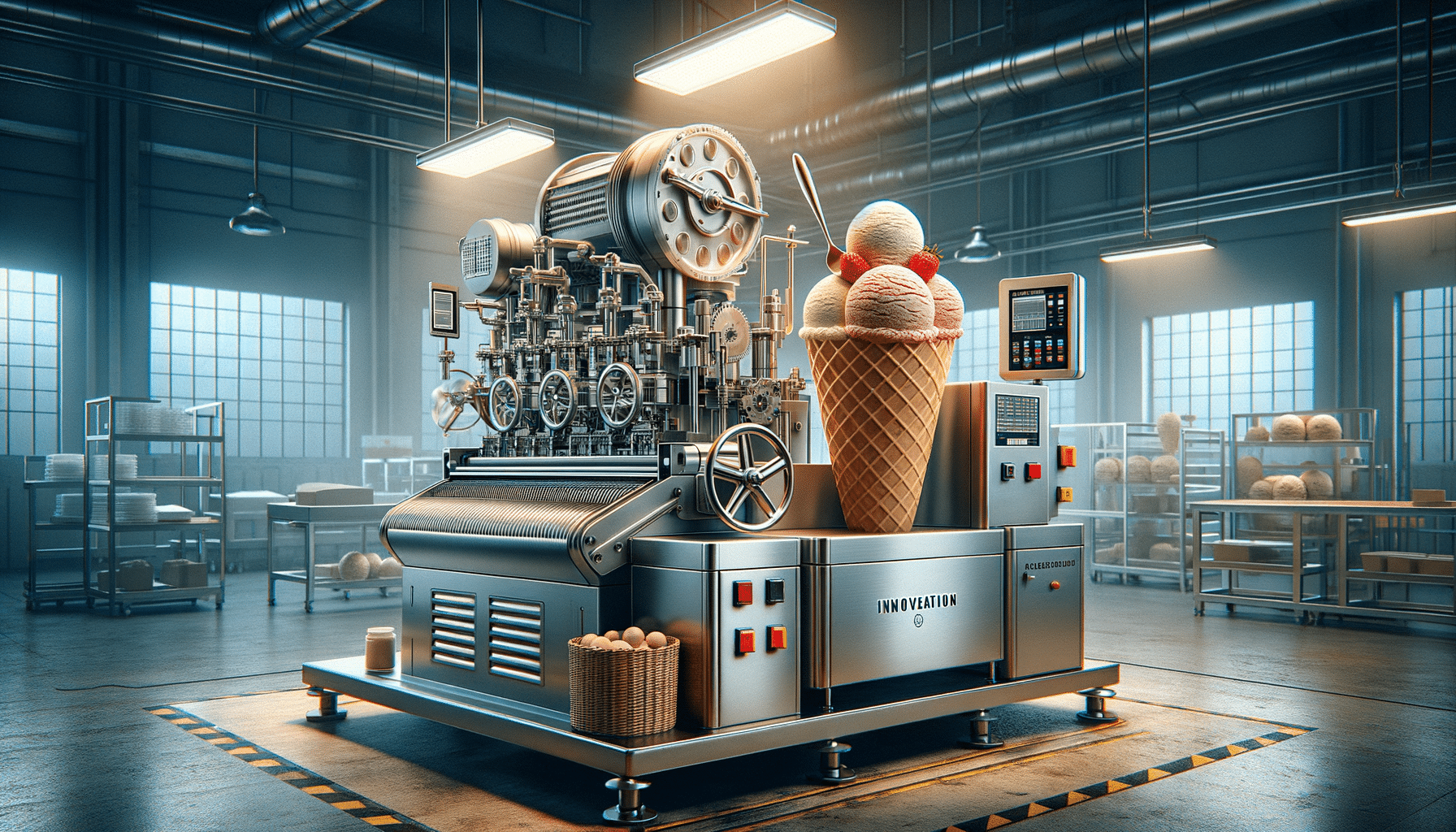

Today’s industrial ice cream makers are a marvel of engineering, designed to meet the high demands of modern consumers. These machines not only increase production capacity but also enhance the quality and consistency of the ice cream produced. With advancements in technology, manufacturers can now produce a wide variety of flavors and textures, catering to diverse consumer preferences.

Key innovations in this field include automated mixing and freezing processes, which ensure uniformity and reduce production time. Additionally, the integration of smart technology allows for precise control over temperature and mixing speeds, resulting in a superior product. As we delve deeper into the capabilities of modern ice cream makers, it becomes clear that they are an essential component in the food and drink industry.

Key Features of Modern Ice Cream Makers

Modern ice cream makers are equipped with a range of features that enhance their functionality and efficiency. One of the most notable advancements is the incorporation of automated systems that streamline the production process. These systems allow for consistent mixing and freezing, which is crucial for maintaining the quality of the final product.

Another significant feature is the ability to produce a variety of textures and flavors. With customizable settings, manufacturers can experiment with different ingredients and techniques to create unique products. This flexibility is vital in an industry that thrives on innovation and consumer satisfaction.

Furthermore, modern ice cream makers are designed with energy efficiency in mind. Many models incorporate eco-friendly technologies that reduce power consumption without compromising performance. This not only benefits the environment but also reduces operational costs for businesses.

Some of the standout features of these machines include:

- Advanced refrigeration systems for precise temperature control

- Automated cleaning cycles to maintain hygiene standards

- User-friendly interfaces for easy operation

These features make modern ice cream makers an invaluable asset in the production of high-quality ice cream.

The Role of Technology in Ice Cream Production

Technology plays a pivotal role in the production of ice cream, transforming what was once a labor-intensive process into a streamlined operation. The integration of digital controls and sensors in industrial ice cream makers allows for real-time monitoring and adjustments, ensuring optimal conditions throughout the production cycle.

One of the key technological advancements is the use of programmable logic controllers (PLCs) that automate various stages of production. This automation reduces human error and increases efficiency, allowing manufacturers to produce larger quantities without sacrificing quality.

In addition to automation, technology has enabled the development of more sophisticated freezing techniques. Rapid freezing methods, such as liquid nitrogen freezing, help maintain the texture and flavor of the ice cream by preventing the formation of large ice crystals.

Moreover, data analytics is becoming increasingly important in the industry. By analyzing production data, manufacturers can identify trends and optimize processes for better results. This data-driven approach not only improves product quality but also enhances the overall efficiency of the production line.

Overall, the role of technology in ice cream production is indispensable, driving innovation and enabling manufacturers to meet the ever-growing demands of consumers.

Challenges and Opportunities in the Ice Cream Industry

While the ice cream industry has seen significant advancements, it also faces several challenges. One of the primary concerns is the increasing demand for healthier alternatives. Consumers are becoming more health-conscious, seeking products with reduced sugar and fat content. This shift in consumer preferences presents an opportunity for manufacturers to innovate and develop new formulations that cater to these needs.

Another challenge is the fluctuating cost of raw materials. Ingredients such as dairy and sugar are subject to market volatility, impacting production costs. Manufacturers must navigate these fluctuations while maintaining competitive pricing for their products.

Despite these challenges, the industry is ripe with opportunities. The growing popularity of artisanal and craft ice creams has opened new avenues for small-scale producers. These niche markets allow for creativity and experimentation, attracting consumers looking for unique flavors and experiences.

Furthermore, the global expansion of the ice cream market presents opportunities for growth. With rising disposable incomes and changing lifestyles, demand for ice cream is increasing in emerging markets. Manufacturers can capitalize on this trend by expanding their product offerings and distribution networks.

In conclusion, while the ice cream industry faces challenges, it also offers numerous opportunities for innovation and growth. By staying attuned to consumer preferences and leveraging technological advancements, manufacturers can continue to thrive in this dynamic market.

Conclusion: The Future of Ice Cream Makers

The future of ice cream makers looks promising, with continued advancements in technology and innovation. As consumer preferences evolve, manufacturers will need to adapt and embrace new trends to remain competitive. The integration of smart technology and sustainable practices will play a crucial role in shaping the future of the industry.

One of the key trends to watch is the rise of plant-based and dairy-free alternatives. As more consumers seek these options, ice cream makers will need to develop machines capable of handling diverse ingredients and formulations. Additionally, the focus on sustainability will drive the development of energy-efficient models that minimize environmental impact.

In summary, the ice cream industry is poised for growth and transformation. By embracing innovation and staying responsive to market demands, manufacturers can continue to delight consumers with delicious and diverse offerings. The journey of ice cream makers is a testament to the power of technology and creativity in the culinary world.

Leave a Reply