The Evolution of Industrial Machines

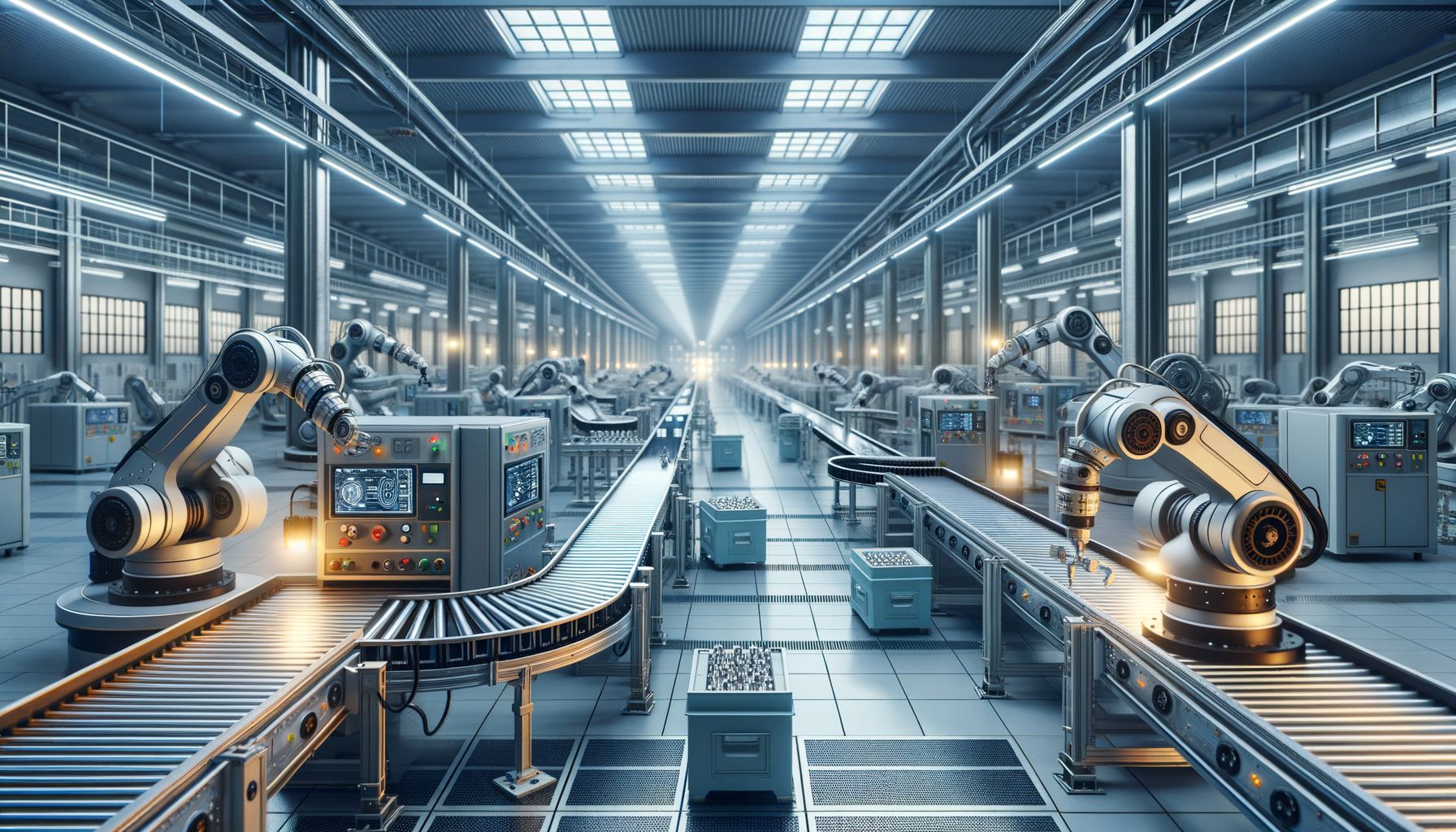

Industrial machines have undergone remarkable transformations over the decades. From the steam engines of the 18th century to the sophisticated automation systems of today, these machines have consistently pushed the boundaries of efficiency and productivity. The Industrial Revolution marked the beginning of mechanization, with machines taking over manual labor tasks, thereby increasing production rates and reducing costs. As technology advanced, so did the capabilities of industrial machines. The introduction of electricity and later, computer technology, revolutionized the way industries operated. Today’s machines are not only faster and more efficient but also smarter, capable of performing complex tasks with precision.

Modern industrial machines are equipped with sensors and IoT capabilities, allowing for real-time monitoring and data analysis. This integration of technology enables predictive maintenance, reducing downtime and extending the lifespan of machinery. As industries continue to evolve, the role of industrial machines becomes increasingly crucial, driving innovation and economic growth.

Types of Industrial Machines and Their Applications

Industrial machines come in various forms, each designed for specific tasks and applications. Among the most common types are:

- CNC Machines: Computer Numerical Control (CNC) machines are used for precise cutting, drilling, and milling. They are widely used in manufacturing sectors like automotive and aerospace.

- Robots: Industrial robots are employed for tasks that require high precision and repeatability, such as welding, painting, and assembly.

- 3D Printers: These machines have revolutionized prototyping and small-scale manufacturing by allowing for rapid production of complex parts.

- Packaging Machines: Essential in the food and beverage industry, these machines automate the packaging process, ensuring consistency and efficiency.

Each type of machine plays a vital role in its respective industry, contributing to the overall productivity and efficiency. By understanding the applications and benefits of these machines, businesses can make informed decisions about their investments in technology.

Benefits of Implementing Advanced Machines

The implementation of advanced industrial machines offers numerous benefits to businesses. Primarily, these machines enhance productivity by automating repetitive tasks, allowing human workers to focus on more strategic activities. This shift not only increases output but also improves the quality of products by minimizing human error.

Moreover, advanced machines contribute to cost savings. While the initial investment may be significant, the long-term benefits of reduced labor costs, decreased waste, and lower maintenance expenses can outweigh the upfront costs. Additionally, the precision and consistency offered by these machines lead to higher customer satisfaction, as products meet exact specifications with minimal defects.

In a competitive market, staying ahead often requires adopting the latest technology. By integrating advanced industrial machines, businesses can improve their operational efficiency, reduce lead times, and respond more effectively to market demands.

Challenges and Considerations in Adopting Industrial Machines

While the benefits of industrial machines are clear, businesses must also consider the challenges associated with their adoption. One of the primary concerns is the cost of acquisition and implementation. High initial costs can be a barrier for small and medium-sized enterprises, making it essential to evaluate the return on investment carefully.

Another challenge is the need for skilled personnel to operate and maintain these machines. As technology becomes more complex, the demand for trained technicians and engineers increases. Investing in employee training and development is crucial to ensure smooth operations and maximize the potential of the machines.

Furthermore, the integration of new machines into existing systems can be complex and may require significant adjustments. Businesses must plan and execute the integration process carefully to avoid disruptions and ensure a seamless transition.

The Future of Industrial Machines

The future of industrial machines looks promising, with ongoing advancements in technology set to drive further innovation. Artificial intelligence and machine learning are expected to play a significant role, enabling machines to learn from data and improve their performance over time. This evolution will lead to even greater levels of automation and efficiency.

Additionally, the trend towards sustainability is influencing the development of industrial machines. Manufacturers are focusing on creating energy-efficient machines that minimize environmental impact. This shift not only benefits the planet but also aligns with the growing demand for eco-friendly practices in industries.

As industries continue to embrace digital transformation, the role of industrial machines will expand, offering new opportunities for growth and development. By staying informed about the latest trends and technologies, businesses can position themselves at the forefront of innovation and remain competitive in an ever-evolving market.

Leave a Reply