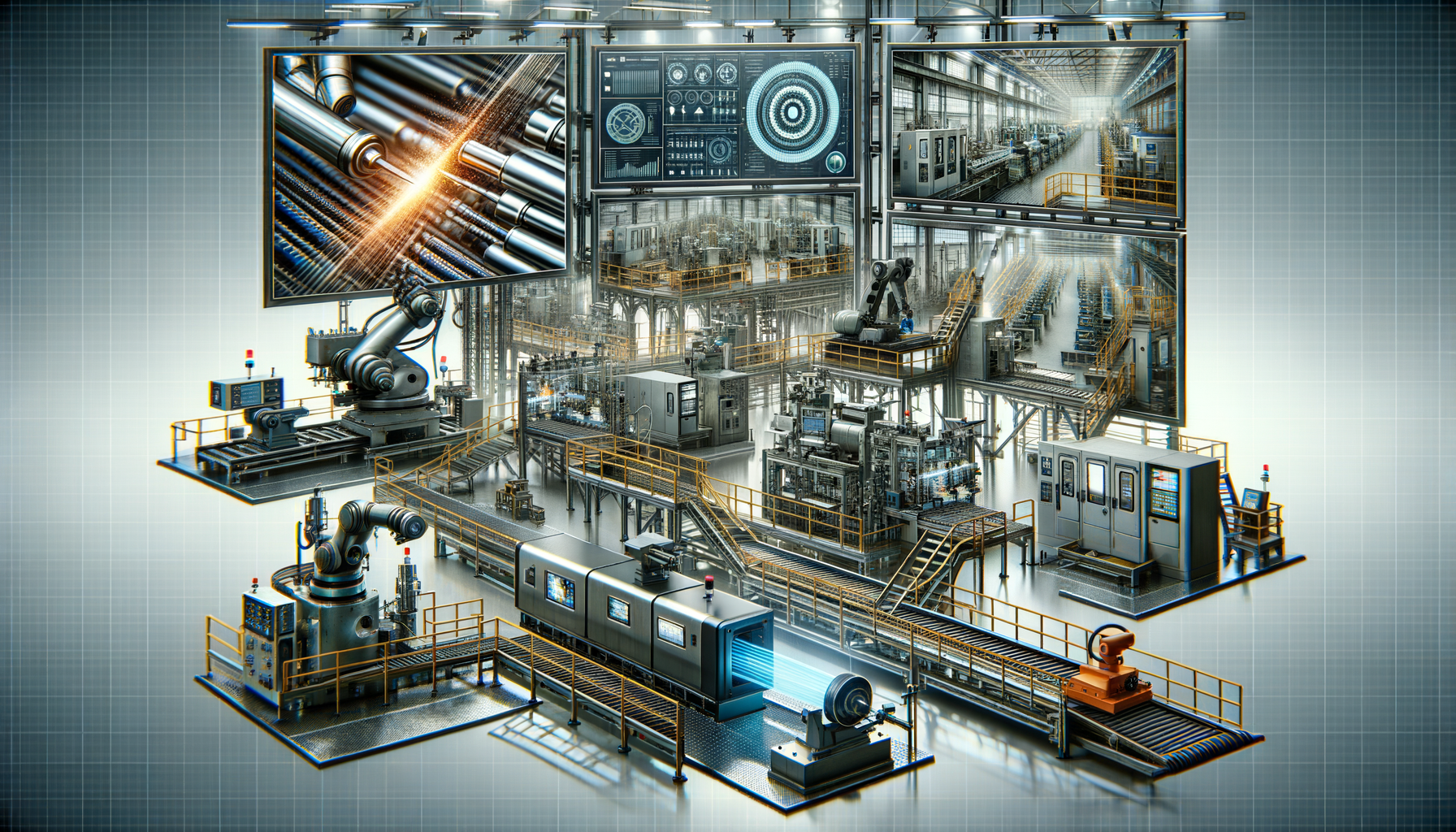

Introduction to Industrial Machines

Industrial machines have become indispensable in modern manufacturing and production environments. These machines are designed to perform complex tasks with precision and speed, thereby enhancing operational efficiency. From assembly lines to packaging, industrial machines play a crucial role in automating processes that were once manual, labor-intensive, and time-consuming. The integration of these machines into various sectors has revolutionized the way businesses operate, allowing for greater consistency, reduced errors, and increased output.

The Role of Automation in Industrial Machines

Automation is at the core of industrial machines, transforming the landscape of production and manufacturing. By automating repetitive tasks, businesses can significantly reduce the time and labor required to produce goods. This not only improves productivity but also enhances the quality of the output. Automated machines can operate continuously without fatigue, ensuring that production lines run smoothly and efficiently. The use of sensors and robotics further enhances the capabilities of industrial machines, enabling them to perform tasks with high precision and minimal human intervention.

Key benefits of automation in industrial machines include:

- Increased production speed

- Improved accuracy and consistency

- Reduced labor costs

- Enhanced safety for workers

These advantages make automation a valuable investment for businesses looking to stay competitive in today’s fast-paced market.

Impact on Different Sectors

Industrial machines have a profound impact across various sectors, each benefiting uniquely from their capabilities. In the automotive industry, for instance, machines are used for assembling parts, welding, and painting, ensuring that vehicles are produced with high precision and quality. The food and beverage sector relies on machines for tasks such as packaging, labeling, and quality control, which help maintain hygiene standards and reduce waste.

In the textile industry, machines are used for spinning, weaving, and dyeing, enabling mass production of fabrics with consistent quality. The pharmaceutical sector also benefits from industrial machines, which are used in the production and packaging of medicines, ensuring compliance with stringent regulatory standards.

Overall, the integration of industrial machines into these sectors leads to streamlined operations, enhanced product quality, and increased production capacity.

Technological Advancements in Industrial Machines

The evolution of technology has significantly advanced the capabilities of industrial machines. Innovations such as artificial intelligence (AI) and the Internet of Things (IoT) have enabled machines to become smarter and more connected. AI-powered machines can analyze data in real-time, making adjustments to optimize performance and reduce downtime. IoT connectivity allows machines to communicate with each other and with central control systems, facilitating seamless integration and coordination across the production line.

These technological advancements not only improve efficiency but also provide valuable insights into the production process, enabling businesses to make data-driven decisions and improve overall operational effectiveness.

Technological advancements in industrial machines include:

- Real-time monitoring and predictive maintenance

- Enhanced machine learning capabilities

- Greater connectivity and interoperability

- Improved energy efficiency

These innovations are driving the future of industrial machines, making them more versatile and adaptable to changing business needs.

Conclusion: The Future of Industrial Machines

As industrial machines continue to evolve, they will play an increasingly important role in shaping the future of manufacturing and production. The ongoing advancements in technology will further enhance their capabilities, making them even more efficient and versatile. Businesses that invest in these machines stand to gain a competitive edge, as they can optimize their operations and deliver high-quality products to the market faster and more reliably.

The future of industrial machines is bright, with endless possibilities for innovation and improvement. As industries continue to embrace automation and technology, industrial machines will remain at the forefront of this transformation, driving progress and efficiency in the years to come.

Leave a Reply