Introduction to Industrial Grill Machines

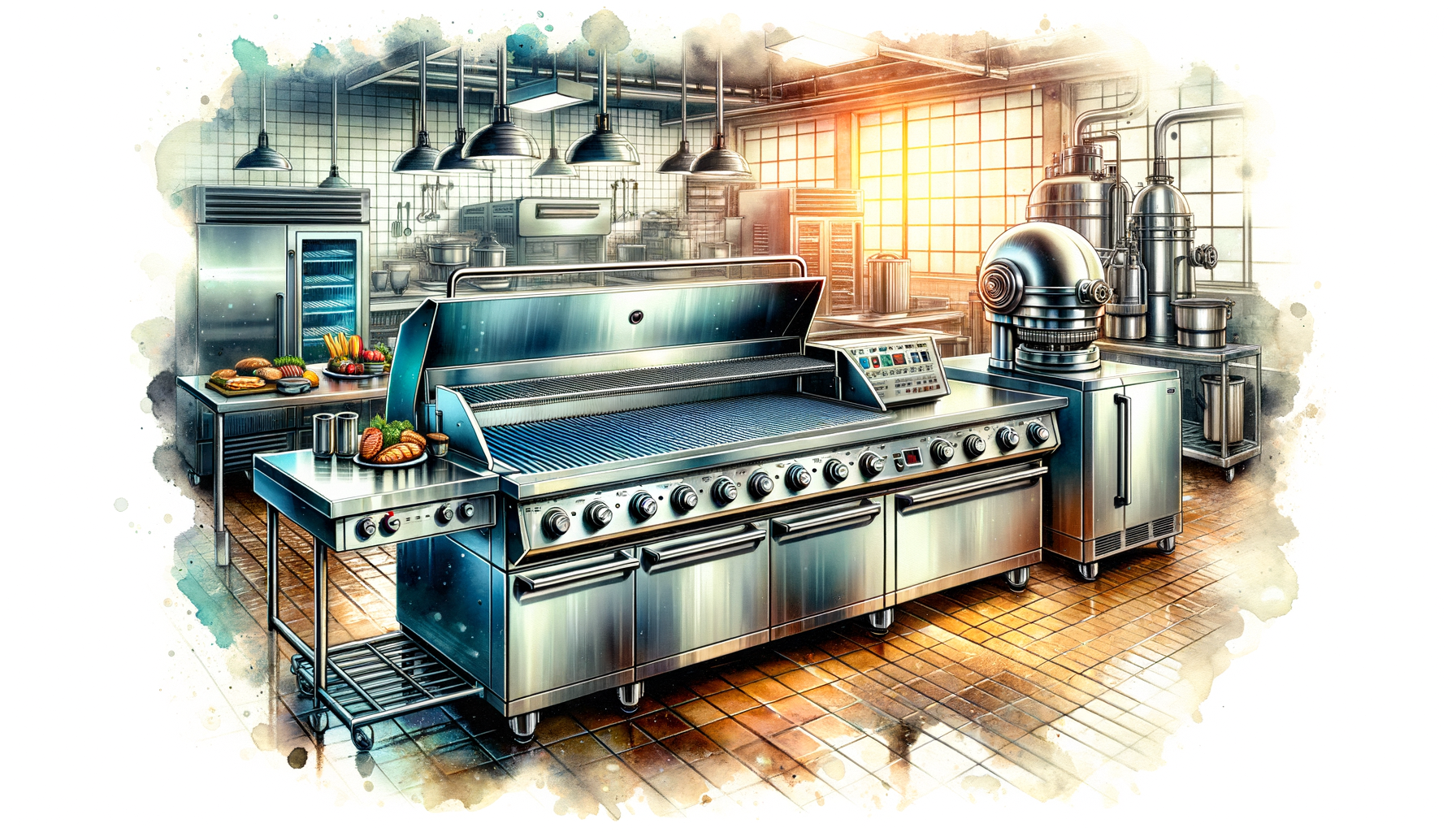

Industrial grill machines are a cornerstone in the world of commercial cooking, offering unparalleled efficiency and durability. These machines are specifically designed to handle the demands of large-scale food preparation, making them indispensable in restaurants, catering services, and food production facilities. The ability to consistently deliver high-quality cooking results is what sets these machines apart from their domestic counterparts.

One of the key benefits of industrial grill machines is their ability to maintain consistent heat across large cooking surfaces. This ensures that food is cooked evenly, reducing the risk of undercooked or overcooked dishes. Additionally, their robust construction allows them to withstand the rigors of daily use, providing reliability that is essential in a fast-paced kitchen environment.

In this article, we will explore the various aspects of industrial grill machines, from their design and functionality to their impact on kitchen efficiency. We will also delve into the different types of grills available and how they can be integrated into various culinary settings.

Design and Functionality of Industrial Grill Machines

The design of industrial grill machines is focused on maximizing efficiency and durability. These machines are typically constructed from high-grade stainless steel, which not only provides strength but also ensures easy cleaning and maintenance. The use of stainless steel also helps in resisting corrosion, an important factor given the high-moisture and high-temperature environment in which these grills operate.

Functionality is another area where industrial grill machines excel. They are equipped with advanced heating elements that provide precise temperature control, allowing chefs to adjust the heat according to the specific requirements of different dishes. Many models also feature multiple cooking zones, enabling simultaneous preparation of various food items without flavor cross-contamination.

Some industrial grill machines come with additional features such as built-in grease management systems, which help in maintaining cleanliness and reducing fire hazards. These systems collect excess grease and channel it away from the heat source, ensuring a safer cooking environment.

Types of Industrial Grill Machines

There are several types of industrial grill machines, each designed to cater to specific cooking needs. The most common types include flat-top grills, charbroilers, and rotisserie grills. Each type offers unique advantages and can be chosen based on the specific requirements of the kitchen.

- Flat-top grills: These are ideal for cooking a wide variety of foods, from pancakes to steaks. Their smooth surface allows for even heat distribution, making them versatile for different cooking techniques.

- Charbroilers: Known for their ability to impart a smoky flavor to food, charbroilers are perfect for grilling meats and vegetables. They are equipped with grates that create distinctive grill marks, enhancing the visual appeal of dishes.

- Rotisserie grills: These grills are designed for slow-cooking meat, ensuring tenderness and flavor. They use a rotating spit to evenly cook large cuts of meat, making them suitable for roasting whole chickens or large roasts.

Understanding the different types of grills and their applications can help kitchen managers select the right equipment to meet their specific culinary goals.

Impact on Kitchen Efficiency

Industrial grill machines have a significant impact on kitchen efficiency by streamlining the cooking process and reducing preparation time. Their ability to handle large quantities of food at once allows chefs to focus on other important tasks, improving overall productivity.

These machines are designed to heat up quickly and maintain consistent temperatures, which is crucial in a busy kitchen where timing is everything. The efficiency of industrial grills also translates to energy savings, as they are often equipped with energy-efficient heating elements that minimize power consumption.

Moreover, the durability and reliability of industrial grill machines mean less downtime due to repairs or maintenance, ensuring that the kitchen can operate smoothly without interruptions. This reliability is particularly important in high-volume settings where any delay can lead to customer dissatisfaction.

Conclusion: Enhancing Culinary Operations

In conclusion, industrial grill machines are essential tools for any commercial kitchen aiming to enhance efficiency and maintain high standards of food quality. Their robust design, versatile functionality, and ability to handle large-scale cooking make them a valuable investment for restaurants, catering services, and food production facilities.

By choosing the right type of grill and incorporating it into the kitchen workflow, culinary professionals can ensure consistent cooking results, improve operational efficiency, and ultimately deliver exceptional dining experiences to their customers. As the demand for high-quality, efficiently prepared food continues to grow, industrial grill machines will remain a vital component in the culinary industry.

Leave a Reply