The Role of Industrial Machines in Modern Manufacturing

Industrial machines have revolutionized the manufacturing landscape, bringing about a paradigm shift in how products are made. These machines are integral to various industries, from automotive to food processing, and have significantly enhanced efficiency and productivity. By automating repetitive tasks, industrial machines reduce human error and increase output consistency. This automation is not just about replacing manual labor; it’s about augmenting human capabilities to achieve what was previously unimaginable.

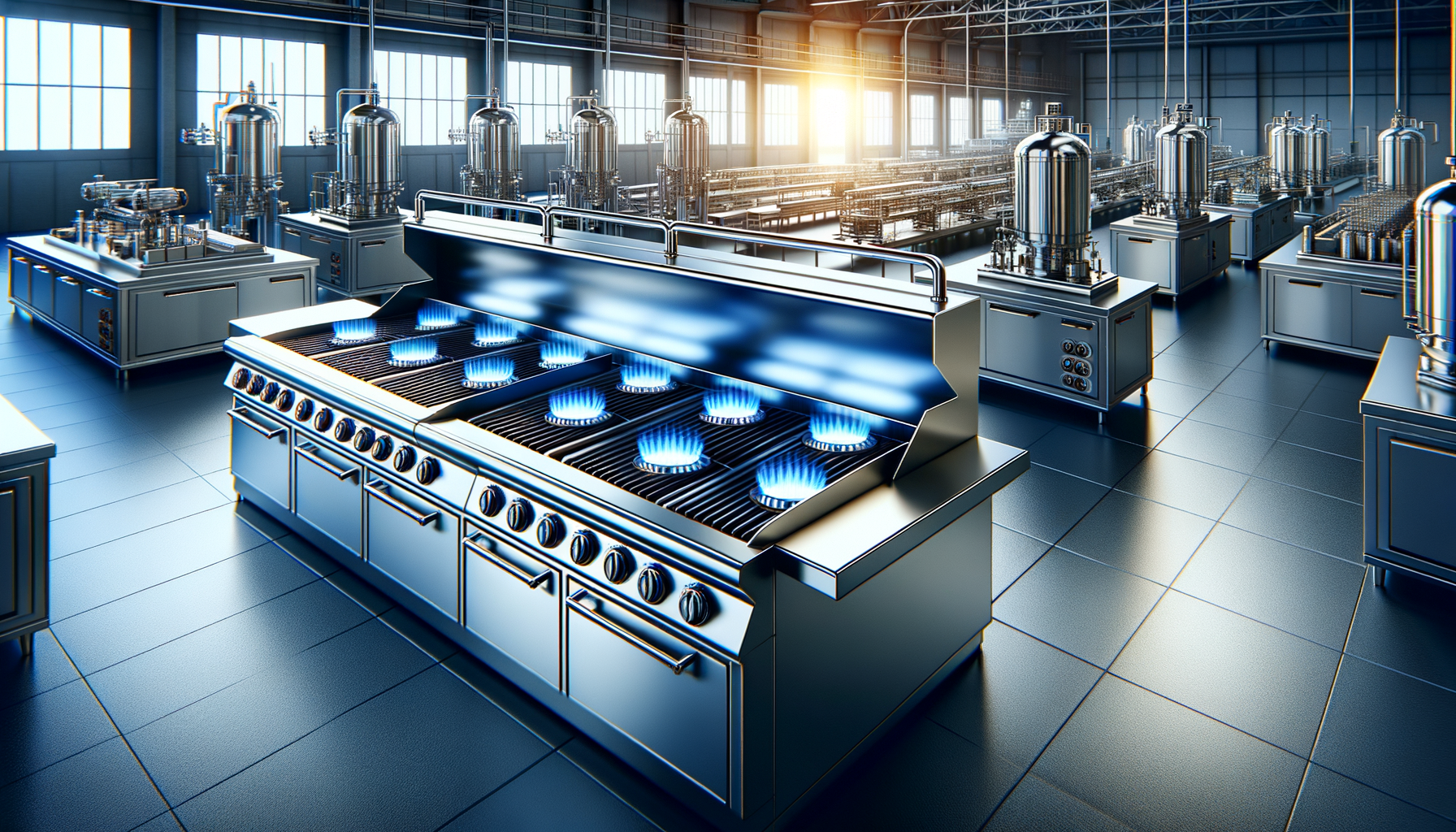

For instance, in the automotive industry, robots and automated systems handle tasks such as welding, painting, and assembly. This not only speeds up production but also ensures precision and safety. Similarly, in the food industry, machines like industrial grills play a pivotal role in mass-producing cooked foods with consistent quality. These machines are designed to handle large volumes, ensuring that the end product meets the required standards every time.

The importance of industrial machines is underscored by their ability to work tirelessly, ensuring that production lines run smoothly and efficiently. This reliability is crucial in industries where downtime can lead to significant financial losses. Moreover, with advancements in technology, these machines are becoming more intelligent and adaptable, capable of performing complex tasks with minimal human intervention.

Types of Industrial Machines and Their Applications

Industrial machines come in various forms, each designed to perform specific tasks. Some of the most common types include:

- Robotic Arms: Used in manufacturing for tasks such as welding, material handling, and assembly.

- Industrial Grills: Essential in the food industry for cooking large quantities of food evenly and efficiently.

- CNC Machines: Utilized for precision cutting, shaping, and drilling in metalworking and woodworking industries.

- Conveyor Systems: Facilitate the movement of materials and products through different stages of production.

Each type of industrial machine has its unique set of applications and benefits. For example, robotic arms are highly valued in the automotive industry for their precision and ability to work in hazardous environments. On the other hand, CNC machines are indispensable in industries requiring high precision and repeatability, such as aerospace and electronics.

Industrial grills, a focus of this article, are particularly important in the food industry. They are designed to cook large batches of food consistently, ensuring that each piece is cooked to perfection. These grills can handle various food items, from meats to vegetables, making them versatile tools in commercial kitchens and food production facilities.

Industrial Grills: A Closer Look

Industrial grills are specialized machines used in the food industry to cook large quantities of food efficiently. These grills are designed to meet the demands of high-volume cooking, ensuring that food is cooked evenly and consistently. They are equipped with advanced features such as temperature control, automated flipping mechanisms, and non-stick surfaces to enhance cooking efficiency.

One of the key advantages of industrial grills is their ability to maintain consistent temperatures, which is crucial for achieving uniform cooking results. This is particularly important in commercial settings where food quality and safety are paramount. Moreover, these grills are built to withstand the rigors of continuous use, making them reliable workhorses in busy kitchens.

In addition to their functional benefits, industrial grills also offer economic advantages. By reducing cooking times and minimizing food waste, they help businesses save on operational costs. Furthermore, their durability and low maintenance requirements mean that they offer a good return on investment over time.

Overall, industrial grills are an essential component of modern food production, helping businesses meet the demands of a growing market while maintaining high standards of quality and efficiency.

Technological Advancements in Industrial Machines

The field of industrial machinery is constantly evolving, with technological advancements driving improvements in efficiency, precision, and safety. One of the most significant developments in recent years is the integration of smart technology and IoT (Internet of Things) into industrial machines.

Smart technology allows machines to communicate with each other and with central control systems, enabling real-time monitoring and adjustments. This connectivity enhances the efficiency of production lines by allowing for predictive maintenance, reducing downtime, and optimizing resource use. For example, an industrial grill equipped with IoT sensors can monitor cooking temperatures and times, sending alerts if any parameters deviate from the set standards.

Another area of advancement is the use of AI (Artificial Intelligence) in industrial machines. AI algorithms can analyze vast amounts of data to optimize machine performance, predict maintenance needs, and even make decisions on the fly. This level of automation and intelligence is transforming industries by reducing the need for human intervention and increasing production capabilities.

These technological advancements are not only improving the efficiency of industrial machines but also enhancing their safety features. Modern machines are equipped with advanced safety mechanisms that protect operators and ensure compliance with industry regulations. As technology continues to advance, we can expect industrial machines to become even more sophisticated, offering new possibilities for innovation and efficiency in manufacturing.

Conclusion: The Future of Industrial Machines

Industrial machines have come a long way, transforming industries and driving economic growth. As technology continues to evolve, these machines will become even more integral to manufacturing processes, offering new opportunities for innovation and efficiency. The integration of smart technology, AI, and IoT is just the beginning of a new era in industrial machinery.

For businesses, investing in modern industrial machines is not just about keeping up with the competition; it’s about staying ahead. These machines offer numerous benefits, from increased productivity to reduced operational costs, making them valuable assets in any industry. As we look to the future, the role of industrial machines will only grow, shaping the way we produce goods and meet the demands of a rapidly changing world.

In conclusion, whether it’s an industrial grill in a bustling kitchen or a robotic arm on an assembly line, industrial machines are the backbone of modern manufacturing, driving efficiency, and innovation across industries.

Leave a Reply