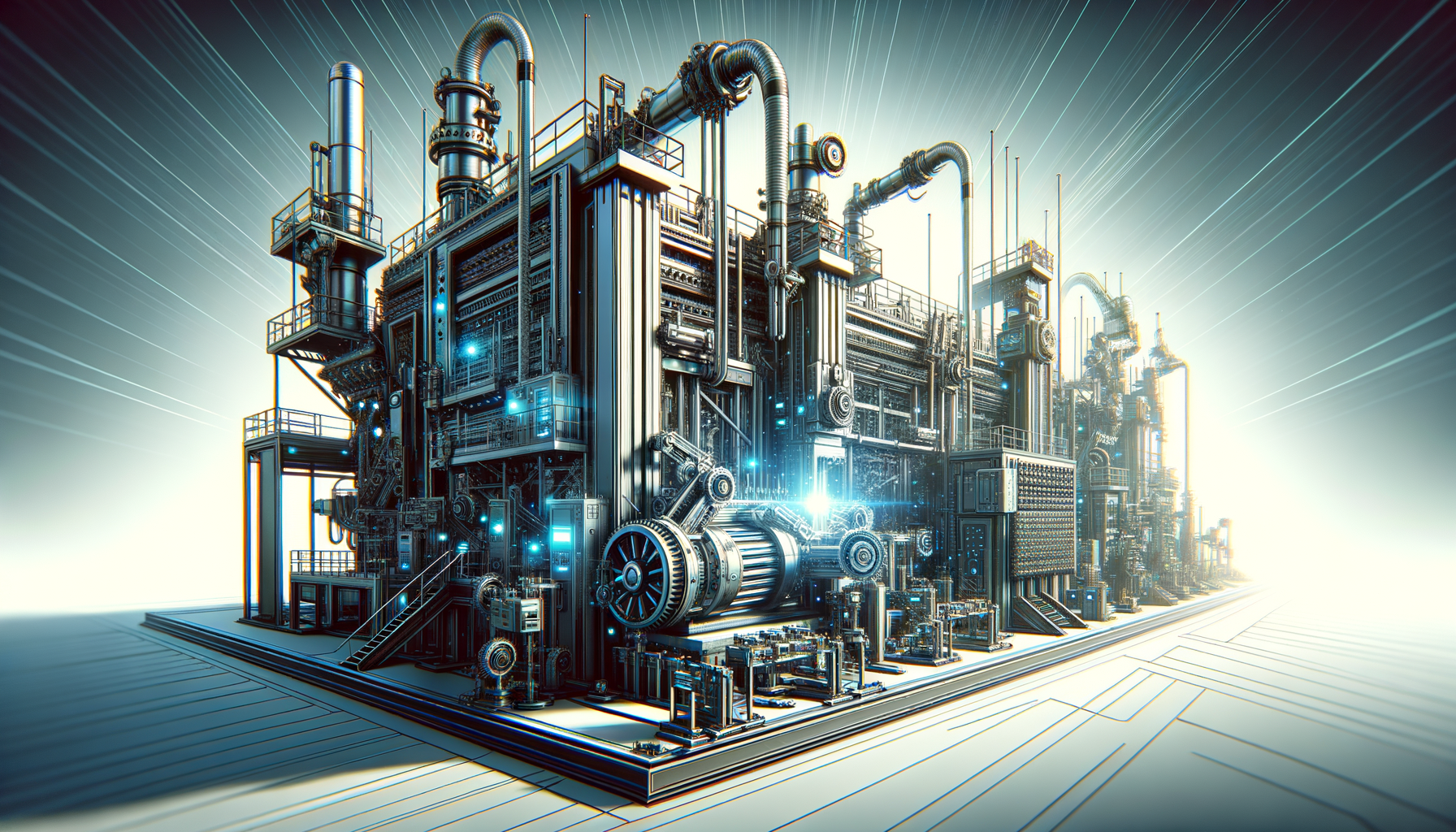

Introduction to Industrial Machines

Industrial machines have revolutionized the way businesses operate, offering unprecedented levels of efficiency and precision. These machines are integral to various sectors, from manufacturing to construction, driving productivity and innovation. In today’s competitive market, understanding the capabilities and benefits of these machines is crucial for any business aiming to enhance its operations.

Types of Industrial Machines

Industrial machines come in various forms, each designed to perform specific tasks. Some of the most common types include:

- Machining Tools: These include lathes, milling machines, and grinders, which are essential for shaping and cutting materials.

- Conveyor Systems: Used for moving materials efficiently across large distances within a facility.

- Robotic Arms: Highly versatile, these machines can perform tasks ranging from assembly to welding.

- Packaging Machines: Designed to automate the packing process, ensuring consistency and speed.

Each type of machine plays a vital role in streamlining operations and reducing manual labor, which, in turn, enhances productivity and safety in the workplace.

Advantages of Using Industrial Machines

Investing in industrial machines offers numerous benefits:

- Increased Efficiency: Machines can operate continuously without fatigue, significantly increasing output.

- Precision and Consistency: Machines are capable of performing tasks with high accuracy, ensuring consistent quality.

- Cost-Effectiveness: While the initial investment might be high, the long-term savings in labor costs and increased production often justify the expense.

- Safety: Machines can handle dangerous tasks, reducing the risk of workplace accidents.

These advantages make industrial machines a valuable asset for any business looking to improve its operational efficiency.

Challenges and Considerations

Despite their benefits, there are challenges associated with the use of industrial machines. These include:

- High Initial Costs: The investment required for purchasing and installing machines can be substantial.

- Maintenance Requirements: Regular maintenance is necessary to ensure machines operate efficiently and have a long lifespan.

- Training Needs: Employees must be trained to operate and maintain these machines effectively, which can be time-consuming and costly.

- Technological Obsolescence: As technology advances, machines can quickly become outdated, requiring further investment in upgrades.

Businesses must weigh these considerations carefully to maximize the benefits of their industrial machines.

Future Trends in Industrial Machinery

The future of industrial machines is promising, with advancements in technology driving innovation. Key trends include:

- Automation: Increasing automation will lead to even greater efficiency and precision in industrial processes.

- Internet of Things (IoT): IoT integration will enable machines to communicate with each other, optimizing operations and reducing downtime.

- Artificial Intelligence (AI): AI will enhance decision-making capabilities, allowing machines to adapt and improve processes autonomously.

- Sustainability: There is a growing emphasis on developing machines that are energy-efficient and environmentally friendly.

By staying informed about these trends, businesses can position themselves at the forefront of industrial innovation.

Conclusion: Embracing Industrial Machines for Success

Incorporating advanced industrial machines into business operations is a strategic move that can lead to significant improvements in productivity and efficiency. While there are challenges to consider, the long-term benefits often outweigh the initial hurdles. By staying abreast of technological advancements and trends, businesses can ensure they remain competitive and successful in an ever-evolving industrial landscape.

Leave a Reply