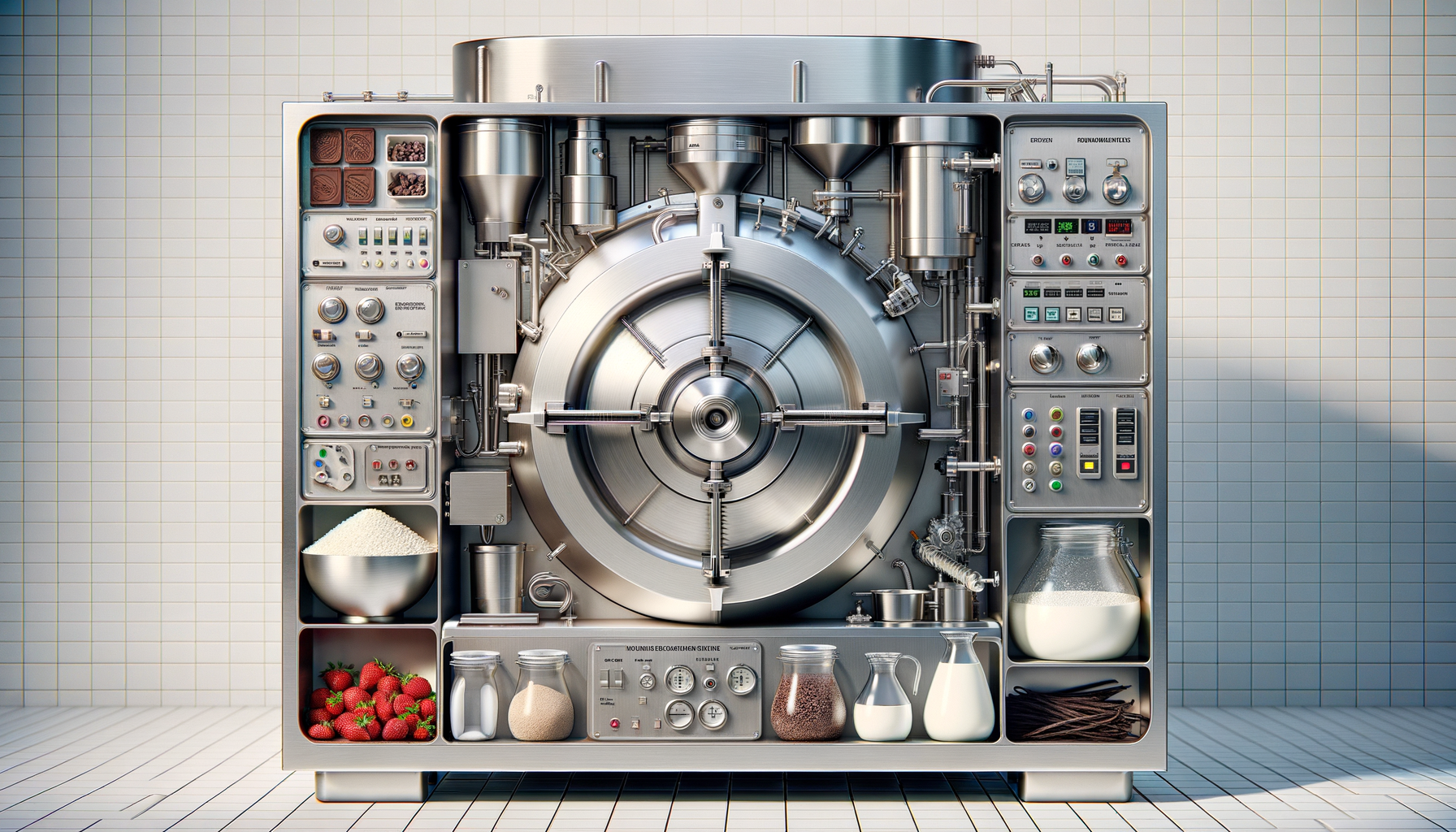

The Role of Industrial Ice Cream Machines

In the world of frozen desserts, industrial ice cream machines play a pivotal role in producing creamy and flavorful ice cream on a large scale. These machines are designed to meet the demands of high-volume production while maintaining the quality and consistency that consumers expect. By carefully controlling temperature and mixing processes, industrial ice cream machines ensure that each batch of ice cream meets the desired texture and taste.

Industrial ice cream machines are engineered to handle a wide range of ingredients, allowing for the creation of diverse and innovative flavors. By incorporating quality ingredients, manufacturers can produce ice cream that stands out in the market. The machines’ precision in mixing and freezing ensures that these ingredients are evenly distributed, resulting in a consistently delicious product.

The efficiency of these machines is crucial for businesses looking to meet the demand for ice cream, especially during peak seasons. By balancing speed and quality, industrial ice cream machines help manufacturers maintain a competitive edge while satisfying customer cravings.

Quality Ingredients: The Heart of Exceptional Ice Cream

The quality of ingredients used in ice cream production is a key factor in determining the final product’s taste and texture. Industrial ice cream machines are designed to work seamlessly with a variety of ingredients, from fresh dairy to exotic fruits and spices. This versatility allows manufacturers to experiment with new flavors and cater to diverse consumer preferences.

Using premium ingredients not only enhances the flavor profile of the ice cream but also contributes to its nutritional value. For instance, incorporating real fruit pieces or high-quality chocolate can elevate the taste experience, making the ice cream more appealing to discerning customers.

Furthermore, the machines’ ability to maintain precise temperature control ensures that the ingredients retain their natural flavors and textures throughout the production process. This attention to detail is essential for creating ice cream that delights the senses and keeps customers coming back for more.

Balancing Efficiency and Quality in Ice Cream Production

In the competitive ice cream industry, balancing efficiency and quality is crucial for success. Industrial ice cream machines are designed to optimize production processes, allowing manufacturers to produce large quantities of ice cream without compromising on quality. This balance is achieved through advanced technology that ensures consistent freezing and mixing.

One of the key features of these machines is their ability to produce ice cream at a rapid pace while maintaining the desired texture and flavor. This is achieved through precise control of temperature and mixing speeds, which prevents the formation of ice crystals and ensures a smooth, creamy product.

Additionally, industrial ice cream machines are equipped with features that allow for easy cleaning and maintenance, reducing downtime and increasing overall efficiency. By investing in high-quality equipment, manufacturers can streamline their operations and focus on creating exceptional ice cream that meets consumer demands.

Innovations in Ice Cream Machine Technology

The ice cream industry has seen significant advancements in machine technology, enabling manufacturers to produce ice cream with greater precision and creativity. Modern industrial ice cream machines are equipped with state-of-the-art features that enhance the production process and allow for the creation of unique and innovative flavors.

One of the most notable innovations is the incorporation of automated systems that monitor and adjust the production parameters in real-time. This ensures that each batch of ice cream is produced under optimal conditions, resulting in a consistently high-quality product.

Moreover, advancements in machine design have led to more energy-efficient models that reduce the environmental impact of ice cream production. These machines use less energy while maintaining the same level of performance, making them an attractive option for eco-conscious manufacturers.

By embracing these technological innovations, ice cream producers can stay ahead of industry trends and continue to delight customers with new and exciting flavors.

Conclusion: Meeting Consumer Expectations with Precision

In conclusion, industrial ice cream machines are essential tools for producing high-quality ice cream that meets consumer expectations. By carefully controlling temperature and mixing processes, these machines ensure that each batch of ice cream is creamy and flavorful. The use of quality ingredients further enhances the taste and texture of the final product, making it a favorite among consumers.

As the industry continues to evolve, manufacturers must balance efficiency and quality to remain competitive. By investing in advanced ice cream machine technology, producers can optimize their operations and create innovative flavors that capture the attention of ice cream enthusiasts worldwide.

Ultimately, the success of an ice cream business depends on its ability to deliver a product that delights the senses and keeps customers coming back for more. With the right equipment and ingredients, manufacturers can achieve this goal and thrive in the ever-growing ice cream market.

Leave a Reply