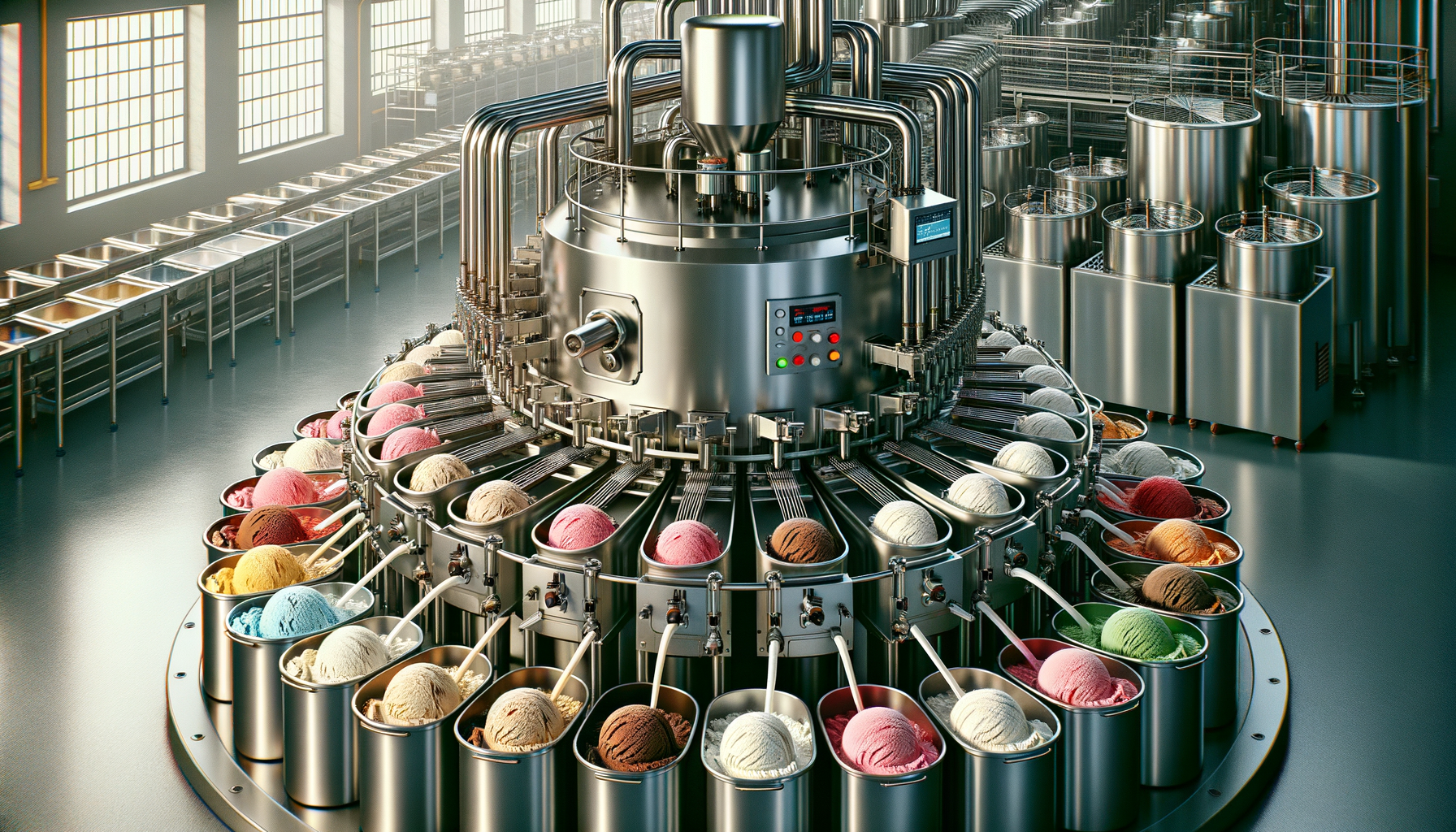

The Role of Industrial Ice Cream Machines

Industrial ice cream machines play a pivotal role in the large-scale production of ice cream, a beloved dessert around the world. These machines are designed to produce high volumes of ice cream efficiently while maintaining the quality and consistency that consumers expect. By combining efficient production with careful temperature control, industrial ice cream machines help deliver creamy, flavorful ice cream. This balance is important for meeting high demand while maintaining quality.

These machines are crucial for businesses that need to meet the demands of large markets, such as supermarkets, restaurants, and ice cream parlors. They allow for the production of varied flavors and textures, catering to diverse consumer preferences. The ability to produce large quantities quickly without compromising on quality is a hallmark of a well-designed industrial ice cream machine.

Moreover, these machines are equipped with advanced features that ensure the ice cream is churned and frozen to perfection. This includes precise temperature controls, mixing paddles, and freezing mechanisms that work together to create a smooth and creamy texture. As consumer expectations continue to rise, the role of industrial ice cream machines becomes even more significant in delivering exceptional products.

Key Features of Industrial Ice Cream Machines

Industrial ice cream machines are equipped with several key features that distinguish them from their smaller, domestic counterparts. Understanding these features can help businesses make informed decisions when investing in such equipment.

- High Capacity: These machines can produce large batches of ice cream, often exceeding hundreds of liters per hour, making them ideal for high-demand environments.

- Efficient Cooling Systems: Advanced cooling systems ensure rapid freezing, which is crucial for maintaining the creamy texture of the ice cream while preventing ice crystal formation.

- Automation: Many industrial machines offer automated processes, reducing the need for constant supervision and allowing for more consistent results.

- Customization Options: The ability to add different ingredients and flavors during the production process allows for a wide range of ice cream varieties.

These features contribute to the machine’s ability to produce high-quality ice cream efficiently, which is essential for businesses looking to scale their operations.

Balancing Speed and Flavor

One of the challenges in industrial ice cream production is balancing speed with flavor. While the primary goal of industrial machines is to produce large quantities quickly, maintaining the quality and taste of the ice cream is equally important.

Speed is achieved through powerful motors and efficient cooling systems that allow for rapid production cycles. However, if not managed properly, this speed can lead to issues such as over-aeration or inadequate mixing, which can affect the ice cream’s texture and flavor.

To counteract these potential pitfalls, manufacturers often incorporate precise control systems that allow operators to adjust the mixing speed, temperature, and other variables. By carefully controlling these parameters, businesses can ensure that their ice cream maintains its rich flavor and creamy texture, even when produced at high volumes.

This delicate balance between speed and flavor is crucial for maintaining customer satisfaction and brand reputation in a competitive market.

Innovations in Ice Cream Machine Technology

The ice cream industry has seen significant technological advancements in recent years, particularly in the design and functionality of industrial ice cream machines. These innovations have transformed the way ice cream is produced, allowing for greater efficiency and creativity.

One notable innovation is the integration of digital technology. Modern machines often come equipped with digital interfaces that allow operators to monitor and adjust production parameters in real-time. This not only improves precision but also enhances the ability to troubleshoot and optimize the production process.

Another advancement is the development of energy-efficient models that reduce the environmental impact of ice cream production. These machines use less energy without compromising on performance, aligning with the growing demand for sustainable business practices.

Additionally, the ability to produce specialized products, such as vegan or low-sugar ice creams, has expanded thanks to advancements in machine technology. This flexibility allows businesses to cater to niche markets and meet diverse consumer needs.

Choosing the Right Ice Cream Machine for Your Business

Selecting the right industrial ice cream machine is a critical decision for any business involved in ice cream production. With a wide range of models and features available, it’s important to consider several factors to ensure the investment aligns with business goals.

Firstly, consider the production capacity required. Businesses should evaluate their current and projected demand to choose a machine that can meet these needs efficiently. It’s also important to consider the types of ice cream products you plan to offer, as some machines offer greater flexibility in terms of flavor and texture customization.

Next, evaluate the machine’s energy efficiency and maintenance requirements. Energy-efficient models can reduce operating costs over time, while machines with straightforward maintenance protocols can minimize downtime and repair expenses.

Finally, consider the level of automation and digital integration. Machines with advanced automation features can streamline production processes and reduce labor costs, while digital interfaces provide greater control and monitoring capabilities.

By carefully considering these factors, businesses can select an industrial ice cream machine that supports their operational goals and enhances their product offerings.

Leave a Reply